Strip building

The Tjelmeland method of strip building

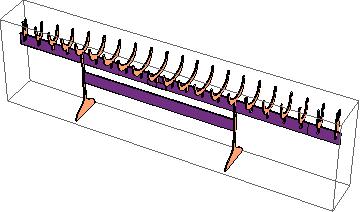

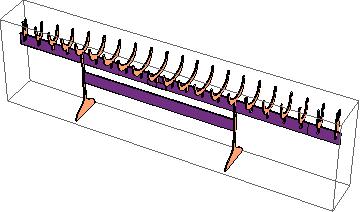

The usual method of strip building is to mount plywood sections on a horizontal bar and mount the wood strips on the outside. Our method takes strip building forward by mounting the sections on an underlying stand and mount the strips on the inside, see the figure below of the stand and sections for the kayak Kjeungskjær. See also a picture from the building of Turøy. One advantage is that it is easier to mount the strips.

The key feature to faster building using the Tjelmeland method is, however, to cut the strips so they fit exactly one place, using a CNC machine. Once the kayak model is described mathematically, it is easy to make the dxf-files for the machine. This removes all time used for cutting, sawing, milling and what not. This has been tested on the kayak Turøy, cutting strips from 4 mm plywood. It is however, premature for us to deliver building sets yet, since the building of Turøy showed that the cutting should be done with a laser head, rather than with a traditional router. This is because the strips tend to be very narrow at the ends since we use variable-width strips and because a laser head would allow us to make placement marks on the strips, which is difficult to achieve on 4 mm thick plywood with a traditional router.

We will, however, experiment with cutting also wood strips with a CNC machine, using a double router. The plan is to have a fully satisfactory method in place when the building of Halten starts by mid-2017.

The picture below shows Tore Tjelmeland cutting plywood for the stand for the building of Turøy.